How to distinguish the quality of nylon cable ties

Views : 347

Author : TENGXIN

Update time : 2021-07-02 15:26:35

Nylon cable ties application field With the development of economy, the advanced application range of socialized mass production is becoming wider and wider, covering almost all fields of application. As a result, the number of manufacturers of nylon cable ties has increased year by year, but the technology, quality, etc. are very different, and the whole consumer goods market is filled with uneven quality.

The first point of concern for nylon cable ties: appearance quality (that can be recognized by the naked eye). Normal plastic products have defects such as flaws, lack of material, burnt, silver wire, bubbles, deformation, shrinkage and so on. These are also easier to appear on nylon cable ties, so you have to pay attention to check their appearance in detail. Although some do not affect the use, they can still induce the potential threat of quality accidents.

The first point of concern for nylon cable ties: appearance quality (that can be recognized by the naked eye). Normal plastic products have defects such as flaws, lack of material, burnt, silver wire, bubbles, deformation, shrinkage and so on. These are also easier to appear on nylon cable ties, so you have to pay attention to check their appearance in detail. Although some do not affect the use, they can still induce the potential threat of quality accidents.

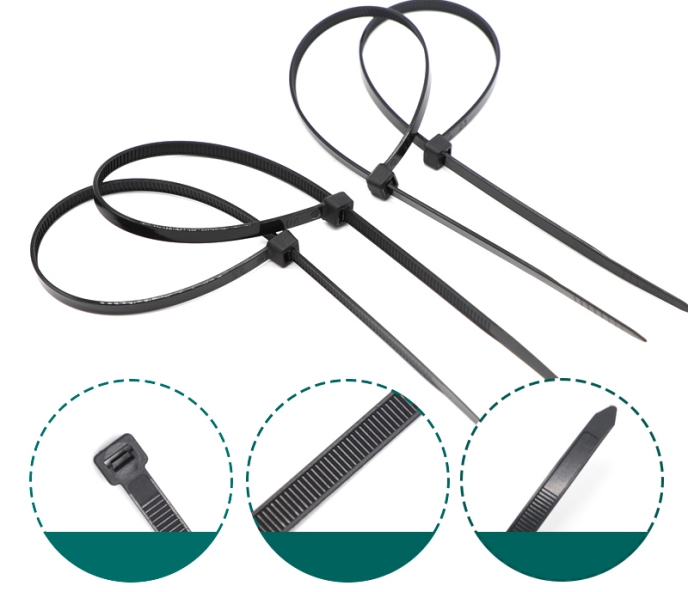

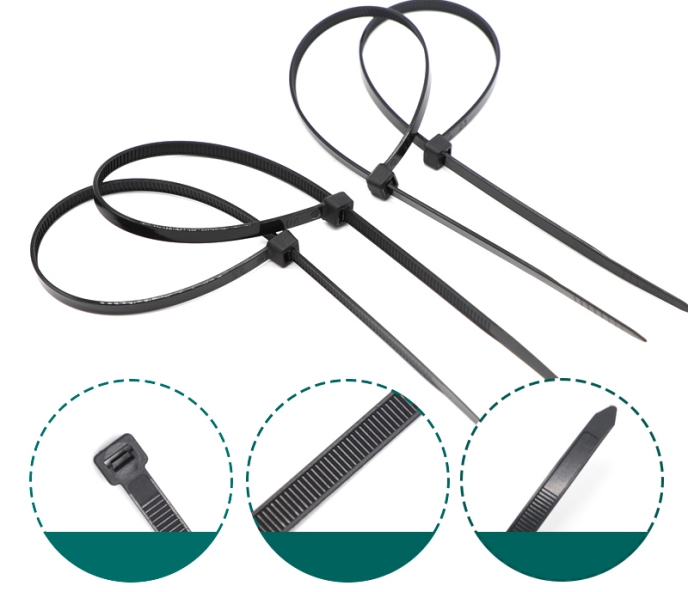

It is worth noting that the key parts of nylon cable ties are the quality of the toothed belt part and the tooth cavity of the head. This is very important. Therefore, the toothed belt part should be carefully observed to avoid residual teeth. The top of the inner surface of the tooth cavity should not There are stepped mold deviation marks, otherwise, there will be a large number of unusable sliding teeth, which will be difficult to insert, which is almost equivalent to waste and cannot be used. These problems require careful attention. Just like a simple edge-cutting phenomenon, if the edge-cutting is too large, the tooth surface of the belt part and the tooth cavity of the head will not fit tightly after insertion, and it is easy to loosen the slippery tooth.

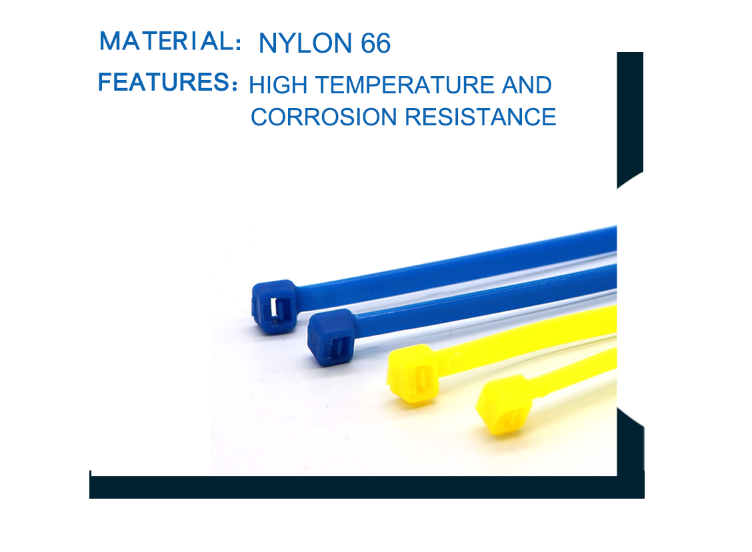

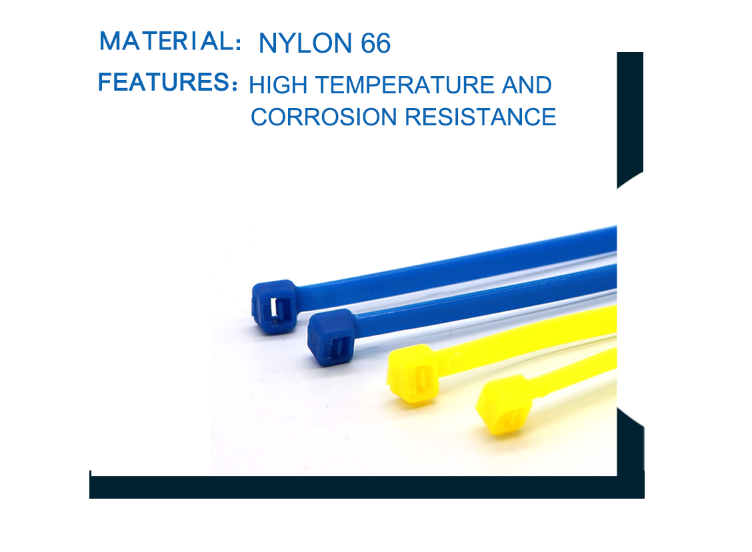

The general rule is that for all products, except for special and necessary requirements, natural products are the best. A good nylon cable tie should be translucent and clear, even if the color is slightly yellow, it should not be a big problem, and it should not be turbid and black. The quality of the materials used is also an important point related to quality. After many times of high-temperature melting and screw shearing, the molecular structure of plastics will change, especially for nylon 66, the raw material for nylon cable ties. Nylon The outstanding abrasion resistance and stretchability of the cable make this product can be used in a wide range of applications.

If you need high-quality nylon cable ties, welcome to consult us,our email: [email protected]

It is worth noting that the key parts of nylon cable ties are the quality of the toothed belt part and the tooth cavity of the head. This is very important. Therefore, the toothed belt part should be carefully observed to avoid residual teeth. The top of the inner surface of the tooth cavity should not There are stepped mold deviation marks, otherwise, there will be a large number of unusable sliding teeth, which will be difficult to insert, which is almost equivalent to waste and cannot be used. These problems require careful attention. Just like a simple edge-cutting phenomenon, if the edge-cutting is too large, the tooth surface of the belt part and the tooth cavity of the head will not fit tightly after insertion, and it is easy to loosen the slippery tooth.

If you need high-quality nylon cable ties, welcome to consult us,our email: [email protected]

Related News

Read More >>